Custom Inground Pool Liners: 10 Stunning Benefits in 2025

Why Custom Inground Pool Liners Are Your Best Pool Investment

Custom inground pool liners offer the perfect blend of style, durability, and cost-effectiveness for your backyard oasis. Unlike standard liners, these are manufactured to your exact pool dimensions and design preferences, ensuring a perfect fit every time.

Key benefits of custom inground pool liners:

- Perfect fit – Computer-designed to match your pool’s exact shape and size

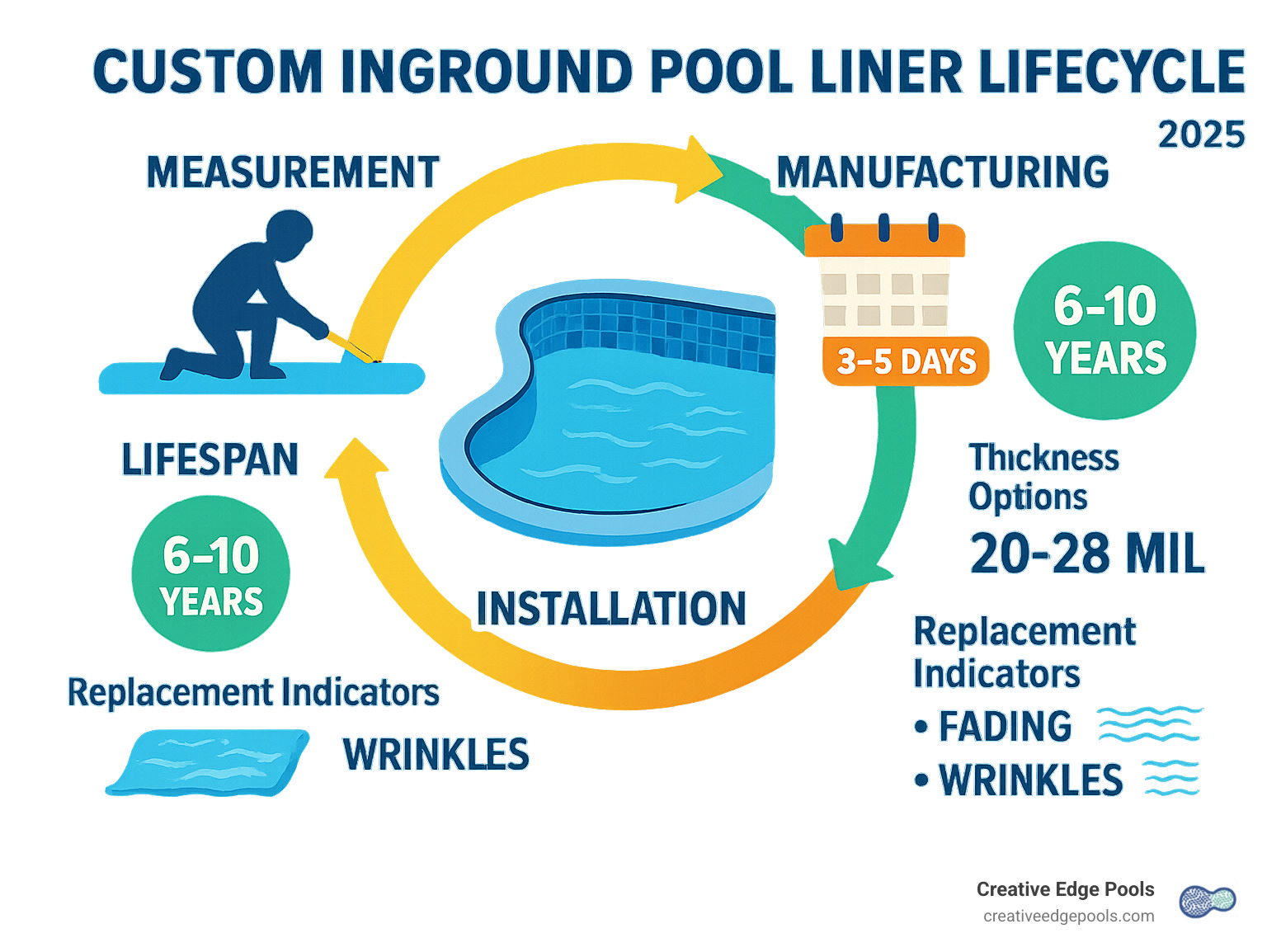

- Fast production – Custom liners ship in 3-5 business days outside peak season

- Extensive customization – Choose from hundreds of patterns, colors, and textures

- Improved durability – Available in 20, 27, and 28 mil thickness with UV inhibitors

- Cost-effective – Less expensive than gunite or fiberglass pool surfaces

- Easy replacement – Typical lifespan of 6-10 years with straightforward installation

Whether you’re building a new pool or replacing an aging liner, custom options give you complete control over your pool’s appearance. Modern vinyl liners feature advanced technologies like antimicrobial coatings, seamless floor designs, and slip-resistant textures that weren’t available just a few years ago.

The choice between DIY installation and professional service often depends on your pool’s complexity and your comfort level with the process. While many homeowners successfully install their own liners using detailed measuring guides, intricate shapes or integrated features may require professional expertise.

I’m David Brabant, owner of Creative Edge Pools, and I’ve spent over thirty years in the swimming pool industry working with custom inground pool liners for clients across Massachusetts and New Hampshire. My hands-on experience has shown me that the right liner choice can completely transform a backyard while staying within budget.

Basic custom inground pool liners vocab:

- Inground Pool Liner Replacement

- cost of replacing inground vinyl pool liner

- replacing inground pool liner

Why Choose Custom Inground Pool Liners?

When you’re ready to transform your backyard oasis, custom inground pool liners offer something truly special that mass-produced options simply can’t match. The difference in fit and appearance is remarkable.

The real magic happens in the personalization process. Your pool has its own unique personality, with specific dimensions, curves, and features that make it yours. Custom manufacturing accepts these individual characteristics rather than forcing your pool into a standard mold.

Fast turnaround times make the custom route surprisingly practical. Most manufacturers can produce and ship your personalized liner within 3-5 business days outside of peak season. That’s faster than many people expect for a completely customized product.

Modern custom inground pool liners incorporate advanced technologies that weren’t available even a few years ago. UV inhibitors and acrylic topcoats now come standard, protecting your investment from sun damage and chemical exposure. These protective features significantly extend the liner’s lifespan compared to older versions.

The thickness options available today also provide better value than ever before. While 20 mil liners remain popular for budget-conscious homeowners, 27 and 28 mil options deliver improved durability for high-traffic pools or harsh New England winters.

Seamless technology has revolutionized how custom liners look and perform. Advanced heat-welding techniques create stronger, more attractive seams that virtually disappear once installed.

| Pool Type | Initial Cost | Maintenance | Lifespan | Customization |

|---|---|---|---|---|

| Vinyl Liner | Low | Low | 6-10 years | Extensive |

| Fiberglass | Medium | Low | 20+ years | Limited |

| Gunite | High | Medium | 20+ years | Extensive |

More info about vinyl benefits

Key Benefits of a Custom Vinyl Fit

Exact sizing represents the biggest game-changer when you choose custom manufacturing. Computer-designed liners eliminate the guesswork and potential headaches that come with trying to make standard sizes work. When measurements are taken properly, your custom liner fits like it was made for your pool – because it was.

This precision fit translates directly into leak prevention. Properly fitted liners experience less stress during installation, which means fewer tears and a longer lifespan.

Quick shipping keeps your project timeline on track. Most custom liner manufacturers have streamlined their production processes to deliver your liner within a week of order approval.

Patterns, Colors & Textures That Pop

Today’s options include sophisticated tile borders, realistic stone textures, and eye-catching geometric patterns that complement your overall landscape design.

Full-floor prints can transform your pool bottom into a stunning focal point. Imagine swimming over what appears to be natural stone, intricate mosaics, or even artistic designs that reflect your personal style.

Slip-resistant textures have become increasingly popular, especially for pool steps and shallow areas. These textured surfaces provide crucial safety benefits while adding visual interest to your pool design.

2024 trends show homeowners gravitating toward natural stone appearances and darker colors. Deep blues, charcoal grays, and earth tones create dramatic water colors that photograph beautifully.

AR preview technology now lets you see exactly how your liner choices will look before you commit. These visualization tools help eliminate buyer’s remorse and ensure your final selection matches your vision.

When a Custom Liner Beats a Stock Option

Freeform pool shapes absolutely require custom manufacturing – there’s no way around it. Stock liners simply cannot accommodate the curves, angles, and unique dimensions that make custom-designed pools special.

Older pools often present sizing challenges that custom manufacturing solves beautifully. Pool construction techniques and sizing conventions have evolved over the decades, so a pool built in the 1980s may not match today’s standard liner dimensions.

Integrated features like tanning ledges, built-in seating, or unique step configurations require custom liner design. These features add complexity that stock liners simply cannot handle.

When you’re investing in your backyard oasis, the small price difference between stock and custom options often pays for itself in improved appearance, better fit, and longer lifespan.

Measuring, Manufacturing & Ordering Your Custom Inground Pool Liners

Getting your custom inground pool liners made correctly starts with one critical step: accurate measurements. Taking the time to measure correctly upfront saves you headaches later.

The measuring process begins with precision templates designed specifically for your pool’s shape. These detailed guides walk you through every dimension your manufacturer needs. From the overall length and width to those tricky corner radii, these templates ensure you don’t miss anything important.

Bead types might sound technical, but they’re actually straightforward. About 97% of inground pools use standard bead, which makes the process simple for most homeowners. However, some pools require specialized configurations like overlap or reverse bead.

Corner radii often confuse DIY measurers. Sharp 90-degree corners are easy to measure, but rounded corners require more attention. Whether your pool has 6-inch, 2-foot, or 4-foot radius corners, each measurement needs to be precise for your liner to fit properly.

Once your measurements reach the factory, computer CAD systems take over. This technology translates your dimensions into exact cutting patterns, ensuring accuracy while optimizing material usage. The CAD process also creates the approval drawings you’ll review before production begins.

The 3-5 day production timeline for most custom configurations still amazes me after all these years in the business. Modern manufacturing processes have made custom liners almost as quick to produce as stock options.

Scientific research on measurement accuracy

Step-by-Step Measuring Guide

The right tools make all the difference in getting accurate measurements. You’ll need a 100-foot tape measure along with measuring forms specific to your pool shape. Having a helper ensures your measurements stay level and accurate throughout the process.

Benchmarks provide the foundation for consistent measurements. I always recommend using your pool coping as the primary reference point. All dimensions should relate back to this fixed point to maintain accuracy across all measurements.

My professional tips come from years of experience: measure twice, record once. Take photos of any unusual features or configurations – these visual references help manufacturers understand your pool’s unique characteristics.

From CAD File to Factory Floor

CNC cutting technology ensures your liner dimensions are precise every time. Computer-controlled cutting eliminates human error and provides consistent results. This precision translates directly into better fit and easier installation.

Heat-welded seams create connections that are actually stronger than the surrounding vinyl material. This technology has revolutionized liner durability compared to older adhesive methods.

Quality control processes catch potential issues before liners leave the factory. Each liner undergoes inspection for proper dimensions, seam integrity, and pattern alignment.

Placing Your Order & Approving the Spec Sheet

Instant quote systems make budget planning straightforward. Most manufacturers provide online tools that generate immediate pricing based on your pool dimensions and selected options.

Pattern sign-off prevents miscommunication about your final selection. Manufacturers provide detailed drawings showing how your chosen pattern will appear in your specific pool shape.

Shipping windows become particularly important during peak season. While off-season orders may ship within days, peak season orders require longer lead times.

Installation, Replacement Timing & Costs for Custom Inground Pool Liners

Planning your custom inground pool liner replacement involves understanding timing, costs, and installation options. Most homeowners get 6-10 years from their vinyl liner, though this depends heavily on how well you maintain your pool and the weather conditions it faces.

The lifespan of your liner tells quite a story. Pools that see heavy use from kids and parties, intense sun exposure, or chemical imbalances typically need replacement closer to that 6-year mark. On the flip side, well-maintained pools in moderate climates often stretch to 10 years or beyond. I’ve seen some exceptional cases where careful homeowners got 12-15 years from premium liners.

Seasonal timing can make or break your project experience. Spring and fall installations offer the sweet spot of good weather and contractor availability. Summer installations? That’s when everyone wants their pool work done, which means higher prices and scheduling headaches. Fall replacement gives you all winter to enjoy planning your pool’s new look.

The big decision most homeowners face is DIY versus professional installation. DIY can save you thousands of dollars, but it requires specific tools, patience, and a willingness to learn. Professional installation costs more upfront but comes with expertise and warranty protection that can save headaches down the road.

Here’s something many homeowners don’t expect: hidden costs can sneak up on you. Pool draining, old liner disposal, and surprise structural repairs finded during installation can add unexpected expenses. I always recommend budgeting 10-15% above your quoted costs for these possibilities.

Signals It’s Time to Replace

Your liner will give you plenty of warning signs when replacement time approaches. Fading above the waterline usually shows up first – that telltale sun damage that makes your pool look tired and dated. While fading doesn’t immediately hurt functionality, it’s your liner’s way of saying “start planning for replacement.”

Wrinkles and looseness indicate your liner has lost its elasticity and no longer hugs your pool properly. These saggy areas collect debris and make cleaning frustrating. Worse yet, loose liners experience more stress during use, which accelerates wear and increases your chances of tears.

Leaks represent the most urgent replacement signal. Small punctures might be patchable, but multiple leaks or large tears typically mean your liner has reached retirement age. I’ve seen homeowners spend more money on patches and repairs than replacement would have cost.

Water loss beyond normal evaporation rates suggests potential liner problems. Your pool should lose about 1-2 inches per week to evaporation, but losses beyond this range deserve investigation. Consistent water loss often points to liner issues that need addressing.

Installation Options: DIY or Professional

DIY installation requires specific equipment including a shop vacuum, basic hand tools, and safety gear. That shop vacuum becomes your best friend during installation – it provides the suction needed to set the liner properly against all pool surfaces. Quality tools make the job smoother and reduce the risk of accidentally damaging your new liner.

Vacuum setting represents the most critical skill in liner installation. Proper vacuum technique ensures your liner conforms to every curve and corner without wrinkles or air pockets. This process demands patience and attention to detail, but motivated DIYers can definitely master it with practice.

Safety considerations become paramount when working around water and electricity. Pool installation involves both elements, creating potential hazards that require careful attention. Professional installers carry insurance and training that protect everyone involved in the project.

Permit requirements vary by location but may apply to your liner replacement project. Some municipalities require permits for pool renovations, especially if any structural work gets involved. Checking local requirements before starting work prevents potential legal headaches later.

Budget Breakdown & Financing Tips

Material costs typically range from $3-8 per square foot depending on your liner thickness, pattern complexity, and manufacturer choice. Premium patterns and thicker materials cost more upfront, but the improved durability and stunning appearance often justify the additional investment.

Labor costs vary significantly based on your location and installer experience. Professional installation typically adds $2-5 per square foot to your total project cost. Complex pool shapes or integrated features like tanning ledges may increase labor requirements and push costs higher.

Add-on costs for new steps, safety covers, and other accessories can substantially increase your project total. Planning for these additional features during initial budgeting prevents sticker shock and allows for better financial planning. Sometimes it makes sense to upgrade everything at once rather than piecemeal over time.

Financing options through pool contractors or manufacturers can make larger projects more manageable for your budget. Many contractors offer payment plans or financing programs that spread costs over time. Comparing financing terms and interest rates helps ensure you get the best deal for your situation.

Caring for Your Custom Inground Pool Liners & Eco-Friendly Advances

Taking care of your custom inground pool liners doesn’t have to be complicated, but it makes a huge difference in how long they last. I’ve seen liners that should have lasted 8-10 years fail after just 4-5 years because of poor maintenance.

The key is understanding that vinyl liners are surprisingly tough, but they do have specific needs. With the right attention, they get better with age, but neglect them and you’ll be shopping for a replacement sooner than you’d like.

Chemical balance is absolutely critical for liner health. Your pH should stay between 7.2-7.6 – any higher and the vinyl becomes brittle, any lower and it can actually dissolve the material.

UV protection through covers saves you money in the long run. The sun is vinyl’s biggest enemy, slowly breaking down the material and fading those beautiful patterns you chose. A good pool cover blocks 99% of UV rays when you’re not swimming.

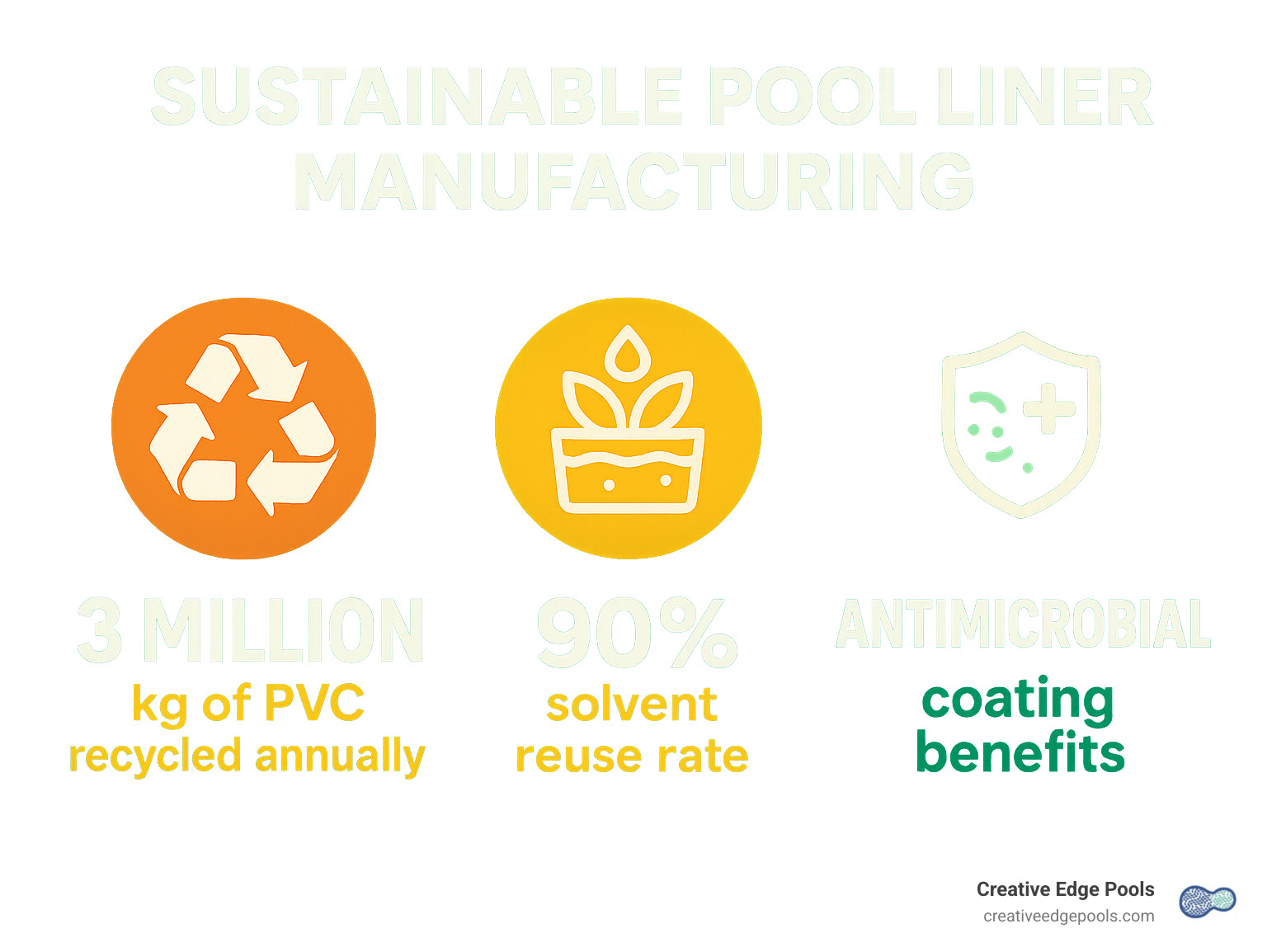

The good news is that the industry is getting much more environmentally conscious. Many manufacturers now run recycling programs for old vinyl liners, turning them into new products instead of sending them to landfills. Some companies recycle over 3 million kilograms of PVC annually.

Antimicrobial coatings are the newest advancement I’m excited about. These coatings actually resist bacteria and algae growth, which means less scrubbing for you and fewer chemicals needed to keep your water clean.

Routine Care to Extend Life

Weekly brushing is your liner’s best friend. Use a brush designed for vinyl pools (never use a wire brush!) and give special attention to areas where debris tends to collect.

Testing your water weekly prevents most liner problems before they start. Those test strips might seem like a hassle, but they’re way cheaper than replacing a liner early. I recommend testing twice a week during heavy use periods.

Winterizing properly protects your investment during the off-season. In our New England climate, this step is non-negotiable. The freeze-thaw cycle can destroy a liner if it’s not winterized correctly.

Patch kits work great for small tears, but don’t go overboard. If you’re patching your liner multiple times a year, it’s probably time to start planning for replacement.

Sustainable & Tech-Forward Options

The pool industry has come a long way in terms of environmental responsibility. Recycled PVC content is now standard in many premium liners, with some manufacturers incorporating millions of pounds of recycled material annually.

Low-VOC inks used in pattern printing are better for everyone. These inks produce the same vibrant colors you love while reducing harmful emissions during manufacturing.

AR visualizers help you make better decisions about patterns and colors, which means fewer returns and less waste. Plus, you can show your family exactly how different options will look before you commit.

Seamless aesthetics through advanced manufacturing create cleaner, more professional-looking installations. Ultra-Seam technology eliminates visible seams on pool floors, giving you that smooth, continuous surface that’s easier to clean and maintain.

The technology keeps getting better, and honestly, it’s exciting to see where the industry is heading. If you want to see some of these new visualization tools in action, check out this latest tech demo – it’s pretty impressive what you can do now before you even order your liner.

Frequently Asked Questions about Custom Inground Pool Liners

How long will a custom vinyl liner really last?

A well-maintained custom inground pool liner typically serves you faithfully for 6-10 years, though I’ve seen some exceptional cases where homeowners get even more life out of them. The lifespan really depends on how well you treat your pool and what Mother Nature throws at it.

Water chemistry plays the biggest role in liner longevity. Pools with consistent pH levels between 7.2-7.6 and proper chlorine balance often reach that 10-year mark. On the flip side, pools with frequent chemical swings or neglected maintenance might need replacement closer to 6 years.

Sun exposure also matters tremendously. Pools with intense southern exposure or minimal shade will show aging faster than those with natural protection. Usage levels factor in too – a pool that hosts daily family gatherings and weekend parties will naturally wear faster than one used for occasional relaxation.

Liner thickness does make a difference, but it’s not as dramatic as you might think. A 28 mil liner will typically outlast a 20 mil liner by 1-2 years under similar conditions, but proper care trumps thickness every time. I’d rather see a well-maintained 20 mil liner than a neglected 28 mil one.

Can I add steps, benches, or tanning ledges to a liner pool?

Absolutely! Custom inground pool liners can accommodate virtually any feature you dream up – steps, benches, tanning ledges, built-in seating, you name it. The beauty of custom manufacturing is that your liner gets precisely cut and shaped to fit around these integrated features like a custom suit.

Here’s the catch though: adding features to an existing pool requires structural modifications that typically happen during liner replacement anyway. This timing actually works perfectly since we need to drain the pool for major construction work regardless.

I often work with clients to plan feature additions during their liner replacement projects. It’s the ideal time to maximize value and minimize disruption to your swimming season. Why go through the hassle of draining and refilling twice when you can do everything at once?

The key is ensuring these features are properly designed and constructed before the new liner goes in. Once that liner is installed, you’re committed to the layout for the next 6-10 years.

What type of warranty should I look for?

Look for manufacturers offering comprehensive warranties that cover both materials and workmanship defects. The industry’s best warranties typically provide 15-year coverage and include protection against manufacturing defects, premature fading, and seam failure.

Some manufacturers offer “no-hassle” warranties that provide replacement or full refund if the liner doesn’t fit properly or has manufacturing defects. These are worth seeking out because they show the manufacturer stands behind their work.

Warranty terms should be clearly written and avoid excessive exclusions that make claims difficult. Be wary of warranties that require specific maintenance procedures or chemical levels that are nearly impossible to maintain consistently. The best warranties protect your investment while allowing normal pool use and maintenance practices.

Pay attention to what’s actually covered too. Some warranties only cover material defects but exclude installation issues, while others provide more comprehensive protection. Understanding these details upfront prevents disappointment if you ever need to make a claim.

Conclusion

Your journey to the perfect backyard oasis doesn’t have to break the bank or take months to complete. Custom inground pool liners represent one of the smartest investments you can make in your outdoor living space, delivering that perfect combination of style, durability, and affordability.

What really excites me about today’s liner technology is how far we’ve come. The antimicrobial coatings that resist bacteria growth, the seamless floor designs that eliminate those annoying dirt-catching seams, and the slip-resistant textures that keep your family safe – these weren’t even options when I started in this business thirty years ago.

The design freedom you get with custom manufacturing is truly remarkable. Whether you’re dreaming of a sophisticated stone-look pattern, a vibrant geometric design, or a classic tile border, your liner can be manufactured to your exact specifications and delivered in just 3-5 business days.

The maintenance ease of vinyl liners continues to surprise homeowners who’ve struggled with other pool surfaces. A quick weekly brushing, proper chemical balance, and your liner will look stunning for years. When it’s time for replacement in 6-10 years, the process is straightforward enough that many homeowners tackle it themselves.

At Creative Edge Pools, we’ve found that liner replacement often becomes the catalyst for complete backyard changes. When clients see how dramatically a new liner changes their pool’s appearance, they often decide to add complementary landscaping, update their pool deck, or install new outdoor lighting.

The cost-effectiveness of custom liners makes these broader improvements possible. Instead of spending tens of thousands on pool resurfacing, you can invest a fraction of that amount in a custom liner and use the savings for other backyard improvements.

Your pool should be a source of joy, not stress. Custom inground pool liners deliver that peace of mind by providing reliable performance, easy maintenance, and the flexibility to refresh your pool’s look as your tastes evolve.

More info about complete backyard changes