Pebble Pool Finish Installation: Master Smooth 2025

Introduction to Pebble Pool Finishes

Pebble pool finish installation is a professional process that transforms a gunite pool shell into a durable, beautiful swimming environment. The installation takes approximately 1-3 days and involves preparing the pool shell, mixing cement with natural aggregates, pneumatically spraying the material, hand-troweling for compaction, exposing the pebbles, and detailed finishing. After installation, a critical 28-day startup period requires specific water chemistry maintenance and daily brushing to ensure proper curing and longevity.

Key Installation Steps:

- Prepare the pool shell – Strip old surfaces, clean, and dampen the concrete

- Mix the materials – Combine cement, pebbles/glass beads, water, and additives

- Apply the finish – Spray evenly and hand-trowel for compaction (within 120 minutes)

- Expose the aggregate – Use water spray or acid wash to reveal pebbles

- Detail and cure – Pressure wash, apply acid solution, fill pool within 24 hours

- Maintain startup chemistry – Follow strict water balance for first 28 days

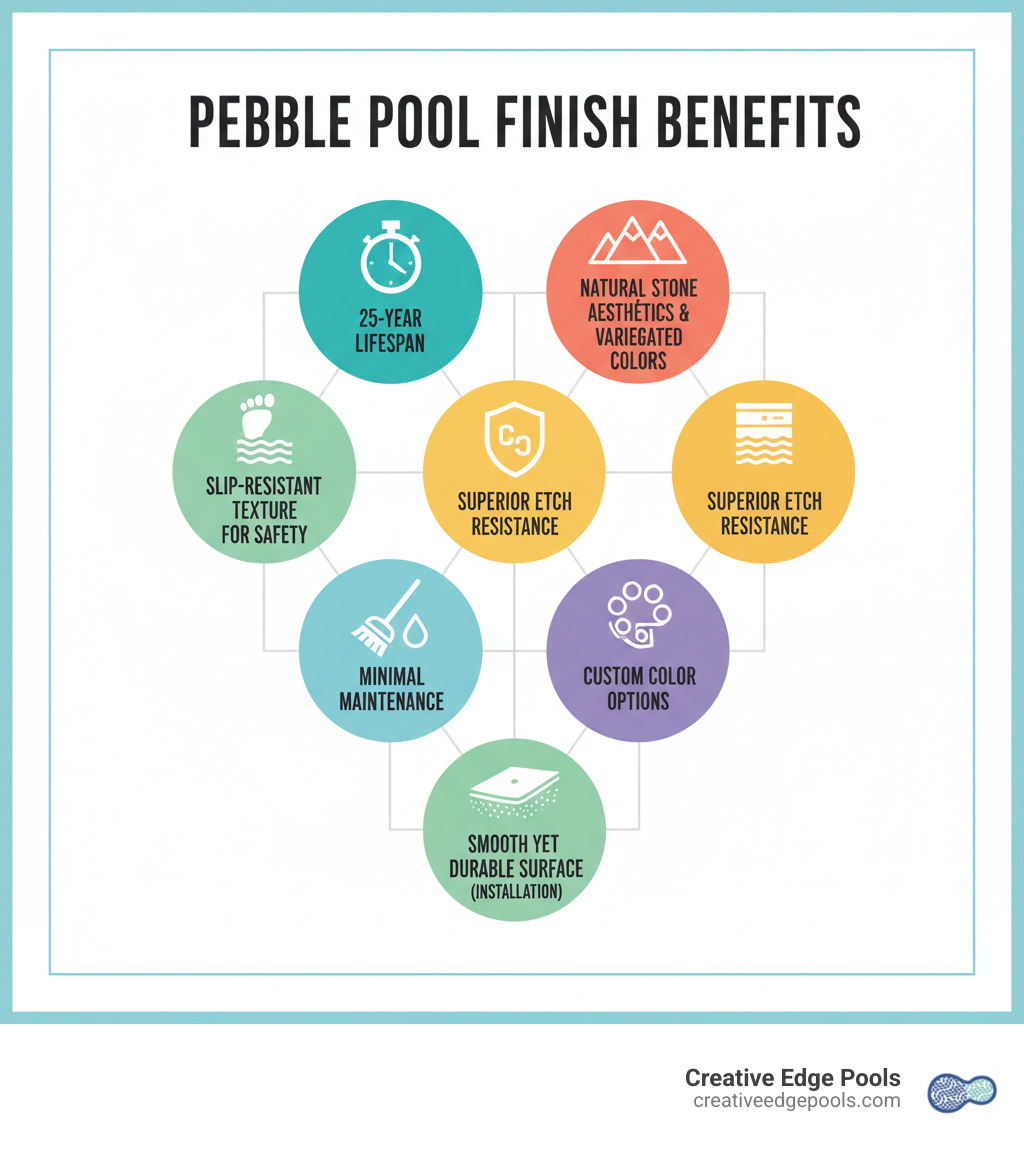

Pebble pool finishes offer proven durability up to 25 years, natural beauty, slip-resistant texture, and etch resistance. They’re available in a wide range of colors and textures, from traditional pebble blends to mini-pebble finishes with polished glass beads for extra water sparkle.

The installation process requires specialized equipment and expertise. It’s not a DIY project—professional, experienced crews ensure proper application, exposure techniques, and curing procedures that vary based on finish type, weather conditions, and pool location.

As the owner of Creative Edge Pools, with over thirty years of hands-on experience in pool construction in Massachusetts and New Hampshire, I’ve learned what makes a pebble pool finish installation successful and durable for decades.

Why Choose a Pebble Finish?

Pebble pool finishes are renowned for durability, often lasting up to 25 years—far longer than many other surfaces. They offer a custom, natural aesthetic with rich color that transforms your pool. The finish is a blend of aggregates like natural pebbles, glass beads, or seashells, creating a unique, slip-resistant texture that improves safety. Pebble finishes also resist etching, a common problem with plaster, and require simple maintenance after curing.

The aesthetic impact is significant, with options for water color ranging from bright crystal blues to deep, serene hues. Different products offer varied textures; for example, some finishes include polished glass beads for a smoother feel and extra water sparkle. The result is a beautiful and sensory swimming experience.

For inspiration on how these finishes integrate into complete outdoor living spaces, take a look at More info about our custom pool designs.

Pebble vs. Mini Pebble: Understanding the Difference

The key difference between standard and mini pebble finishes is the aggregate size, which affects texture and appearance.

Standard Pebble Finishes: These use larger pebbles for a more textured, natural riverbed feel. This provides excellent grip and a rugged, earthy look with rich color variations.

- Pros: Highly natural appearance, excellent slip resistance, robust and durable.

- Cons: Can feel rougher on bare feet for some individuals.

Mini Pebble Finishes (and other fine-aggregate options, including polished glass bead blends): These use smaller pebbles, often with polished glass beads, for a smoother, more refined texture that’s comfortable underfoot. The smaller aggregate creates a more uniform look and can improve water sparkle.

- Pros: Smoother texture for improved comfort, refined aesthetic, often greater water sparkle, still durable and slip-resistant.

- Cons: May be slightly less “natural” looking than a traditional pebble finish, though still incredibly beautiful.

The choice comes down to personal preference for texture and the specific aesthetic you envision for your pool. We’re always happy to discuss the nuances and show you samples to help you find your perfect match!

The Professional Pebble Pool Finish Installation Process

Pebble pool finish installation is a specialized craft demanding professional expertise, not a DIY project. Experienced crews understand the nuances of cement, aggregates, and site-specific challenges. The quality of the installation is what ensures a beautiful finish lasts for decades. The process typically takes 1-3 days, depending on pool size, finish type, and weather conditions. Our team adapts its approach to each project, ensuring precise execution from start to finish.

The foundation of any beautiful pool starts with the gunite shell itself. If you’re curious about how that process works, you can find more info about gunite pool installation on our site.

Step 1: Preparing the Pool Shell for Installation

Proper preparation is critical for a lasting pebble pool finish installation. For remodels, we completely strip the old finish down to the bare concrete. New gunite shells must cure for at least four weeks. The next step is a thorough cleaning to remove all dust, debris, and contaminants that could prevent proper adhesion. The concrete must have a slightly textured surface (like a broom or wood float finish) for the new material to grip. Smooth concrete is not suitable.

Finally, we dampen the shell to ensure a strong bond with the new finish and protect plumbing lines as needed. This meticulous prep work is the foundation of a high-quality result. For pools needing extensive prep or removal, we offer specialized services. You can learn more at more info about swimming pool removal and prep.

Step 2: Application and Finishing Techniques

The application phase of a pebble pool finish installation combines skill, timing, and experience.

Mixing the Perfect Blend: We begin by precisely mixing cement, your chosen aggregate (pebbles, glass beads), pigment, water, and specialized additives to achieve the perfect consistency.

Spraying and Troweling: The mixture is pneumatically sprayed onto the pool surface for even coverage. Our crew immediately hand-trowels the material to compact it, embed the aggregate, and secure it to the shell. This critical step, often completed within 120 minutes of mixing, builds the finish’s strength.

Revealing the Beauty: After troweling, we wash away the top layer of cement with water to reveal the beautiful pebbles and glass beads beneath. The technique and timing depend on the product and weather conditions, highlighting the need for an experienced crew.

The Final Details: Once hardened, the surface is pressure washed and treated with a light acid solution to remove any film, resulting in a pristine finish. This entire process transforms the pool shell within the 1-3 day installation window. We also integrate pools with surrounding hardscapes, as seen in our more info about our masonry work.

The Critical 28-Day Startup and Long-Term Care

After your pebble pool finish installation is complete, the first 28 days are the critical “startup” or curing period. This phase has the greatest impact on the appearance, durability, and longevity of your new finish. Pebble finishes are cement-based and cure in water, releasing a normal plaster dust that affects water chemistry. Diligent monitoring and adjustments are essential. Failure to follow startup procedures can lead to stains, discoloration, and surface roughness, potentially voiding your warranty. For this reason, some homeowners hire a pool care expert for this initial phase.

This critical period also influences the pool’s long-term health. For insights into maintaining your pool’s infrastructure over time, check out More info about gunite pool renovations.

The Initial Pool Fill and Water Chemistry Startup

The initial fill and startup after a pebble pool finish installation is a controlled operation.

Continuous Filling Procedure: The pool must be filled continuously to the middle of the tile line to prevent a waterline mark on the new finish. Use a garden hose and avoid using soft water.

The Initial 28-Day “Do Nots”: Protecting your investment requires following these rules:

- No heaters for the first 14 days.

- No wheeled cleaners for the entire 28-day period (suction cleaners without wheels are okay).

- No chlorine for the first 48 hours.

- No salt for 28-30 days if you have a salt system (use liquid chlorine instead).

- No swimmers or pets during the initial startup phase.

Filtration and Brushing: Run the filter continuously for at least 72 hours (5 days recommended) until plaster dust is gone. Brush the entire pool surface at least once daily for 14 days (twice daily is better) to ensure an even cure.

Water Chemistry Parameters: We test the fill water and adjust it to specific startup parameters. The goal is to maintain a balanced Langelier Saturation Index (LSI) between -0.3 and 0.3 to prevent scaling or etching. Chemicals should be diluted and distributed evenly, never added directly to the skimmer.

| Parameter | Initial 28-Day Startup Range | Ongoing Maintenance Range (After 28 Days) |

|---|---|---|

| pH | 7.0–7.4 | 7.2–7.6 |

| Total Alkalinity | 80–100 PPM | 80–100 PPM |

| Calcium Hardness | 150–250 PPM | 200–300 PPM |

| Total Dissolved Solids | 400–600 PPM | 400–800 PPM |

| Free Chlorine | 1–3 PPM | 1–3 PPM |

| CYA (Stabilizer) | 20–30 PPM | 20–30 PPM |

| LSI (Saturation Index) | -0.3 to 0.3 | -0.3 to 0.3 |

Ongoing Maintenance for a Lasting Pebble Pool Finish Installation

After the 28-day startup, maintaining your beautiful pebble pool finish becomes routine.

Long-Term Water Chemistry: Consistency is key. Continue to maintain balanced water chemistry within the recommended ranges (see table) and keep the LSI between -0.3 and 0.3 to prevent scaling or etching. Regular testing with a quality kit is essential.

Salt Water Chlorination Generator (SWCG) Guidelines: After the initial 28-30 day waiting period, you can add salt and activate your system.

Consequences of Improper Maintenance: Neglecting water chemistry can cause staining, discoloration, etching, and scaling. Importantly, most manufacturers require documented proof of consistent water chemistry for warranty claims, so keep weekly records.

Finding a Qualified Installer: Pebble pool finish installation is a specialized trade. Always choose experienced, industry-recognized crews for the best results. At Creative Edge Pools, we pride ourselves on our expertise. For expert installation and complete backyard design, we are here to help.

And for more tips, tricks, and inspiration for your pool and outdoor living space, be sure to Follow us on Facebook for more pool tips and inspiration!